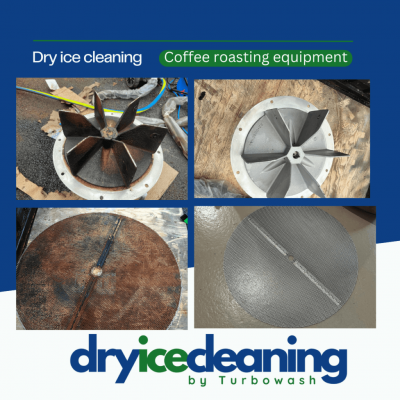

We recently spent a brilliant day dry ice blasting a customer’s coffee roasting machine, and the experience highlighted numerous advantages of this cleaning method. Dry ice blasting is rapidly gaining popularity as an excellent choice for maintaining coffee roasting equipment due to its various benefits:

Key Benefits of Dry Ice Blasting for Coffee Roasting Equipment

1. Non-Abrasive Cleaning: Dry ice blasting is inherently non-abrasive, which means it effectively cleans surfaces without causing any damage. This is particularly important for coffee roasting equipment, which has many sensitive components. Traditional abrasive cleaning methods can scratch or wear down these parts over time, leading to costly repairs or replacements. Dry ice blasting preserves the integrity and lifespan of your equipment.

2. No Secondary Waste: One of the most significant advantages of dry ice blasting is that it leaves no secondary waste. Dry ice, composed of solid CO₂, sublimates directly into gas upon impact, leaving no residue behind. This simplifies the cleanup process immensely compared to traditional methods involving water, solvents, or chemical cleaners, which often require extensive post-cleaning efforts to manage secondary waste and ensure the equipment is completely dry and residue-free.

3. Effective Removal of Residues: Coffee roasting equipment is prone to accumulating various residues, including coffee oils, chaff, and carbon buildup. These residues can affect the flavour and quality of the roasted coffee if not properly removed. Dry ice blasting excels at thoroughly removing these stubborn residues from roasters, cooling trays, grinders, and other components, ensuring that your equipment remains clean and your coffee retains its pure flavour profile.

4. Fast and Thorough Cleaning: Efficiency is critical in any commercial operation, and the fast, thorough nature of dry ice blasting minimises downtime. Traditional cleaning methods can be time-consuming and labor-intensive, often requiring extended periods of disassembly, soaking, scrubbing, and reassembly. Dry ice blasting significantly speeds up the cleaning process, allowing you to return to roasting coffee with minimal disruption to your schedule.

5. Environmentally Friendly: Dry ice is non-toxic and environmentally friendly. Unlike chemical cleaners that may pose health risks and environmental hazards, dry ice blasting uses CO₂, a naturally occurring substance. The process generates no hazardous waste, and the CO₂ used is often reclaimed from industrial processes, making it a sustainable choice for eco-conscious businesses.

Dry ice blasting stands out as a powerful and efficient method for maintaining coffee roasting equipment. Its non-abrasive nature, lack of secondary waste, effective residue removal, and environmentally friendly attributes make it an ideal choice for coffee roasters who aim to uphold high-quality standards and ensure the longevity of their equipment. By incorporating dry ice blasting into your regular maintenance routine, you can achieve superior cleaning results while minimising downtime and environmental impact.

We’re committed to providing advanced, efficient, and eco-friendly solutions to meet your coffee roasting Machine needs. For further inquiries or to make a purchase, feel free to contact us at +353 (0) 1 6978069 or via email at info@turbowash.ie.