Principle of Dry Ice Cleaning

What is dry ice?

The Principle of Dry Ice Cleaning process applies a combination

of three phenomena.

Kinetic Energy

Thermal Shock

Discover the incredible potential of rapid cooling, as impurities delicately crumble away, effortlessly revealing a flawlessly pristine surface.

Sublimation

Principle of Dry ice cleaning

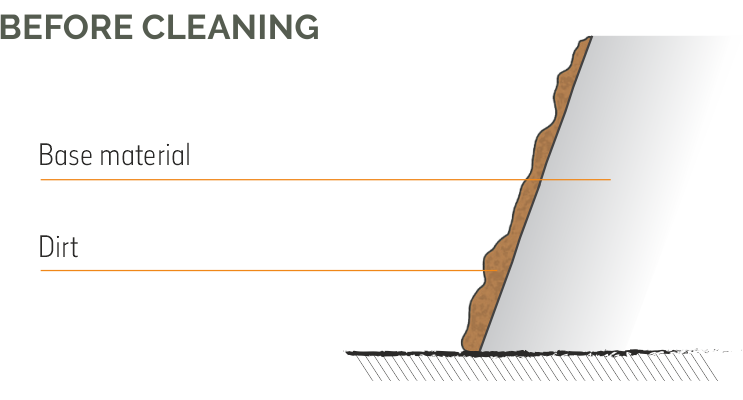

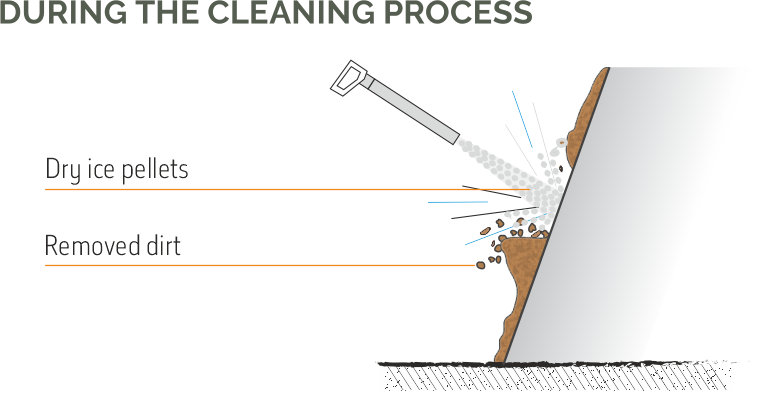

The cleaning process utilises three fundamental phenomena: kinetic energy, thermal shock, and sublimation. This highly effective method removes only residues without generating any secondary waste.

Dry ice allows for a gentle and eco-friendly cleaning of sediment and residue, eliminating the need to dismantle any equipment. This not only saves you valuable time but also significantly reduces costs.

Dry ice has the remarkable ability to halt the growth of bacteria. Additionally, the dry ice cleaning process effectively eliminates the growth of fungi and spores, while diminishing the presence of other biological contaminants. Not only is it non-toxic and odourless, but it is also suitable for all types of surfaces – from sturdy metal and wood to delicate fine wood grains, glass, and textiles.

Advantages of dry ice cleaning

- Environmentally friendly - Using only non-toxic carbon dioxide and compressed air, dry ice cleaning technology is absolutely environmentally friendly and well suited even for food grade applications.

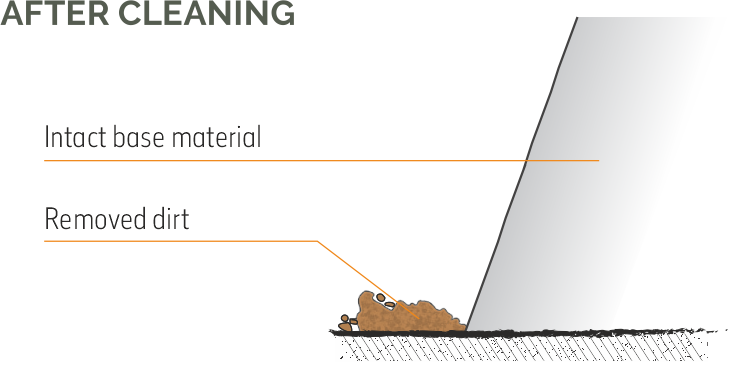

- Minimum waste - Dry ice pellets immediately sublimate in the cleaning process. Therefore, no secondary waste remains after cleaning, only removed dirt that is easy to sweep or vacuum clean.

- Speed and effectiveness - Dry ice blasting minimises the disassembling of machine parts and thus substantially reduces downtimes. Additional cost savings comes from the elimination of the expensive use, removal and disposal of chemical waste.

- Non-abrasive cleaning - Dry ice has ideal non-abrasive properties. It perfectly removes dirt while being mild to surfaces and leaving them undamaged. Dry ice is non-conductive, it is suitable for the cleaning of electrical installations.